Solder Paste

NEW

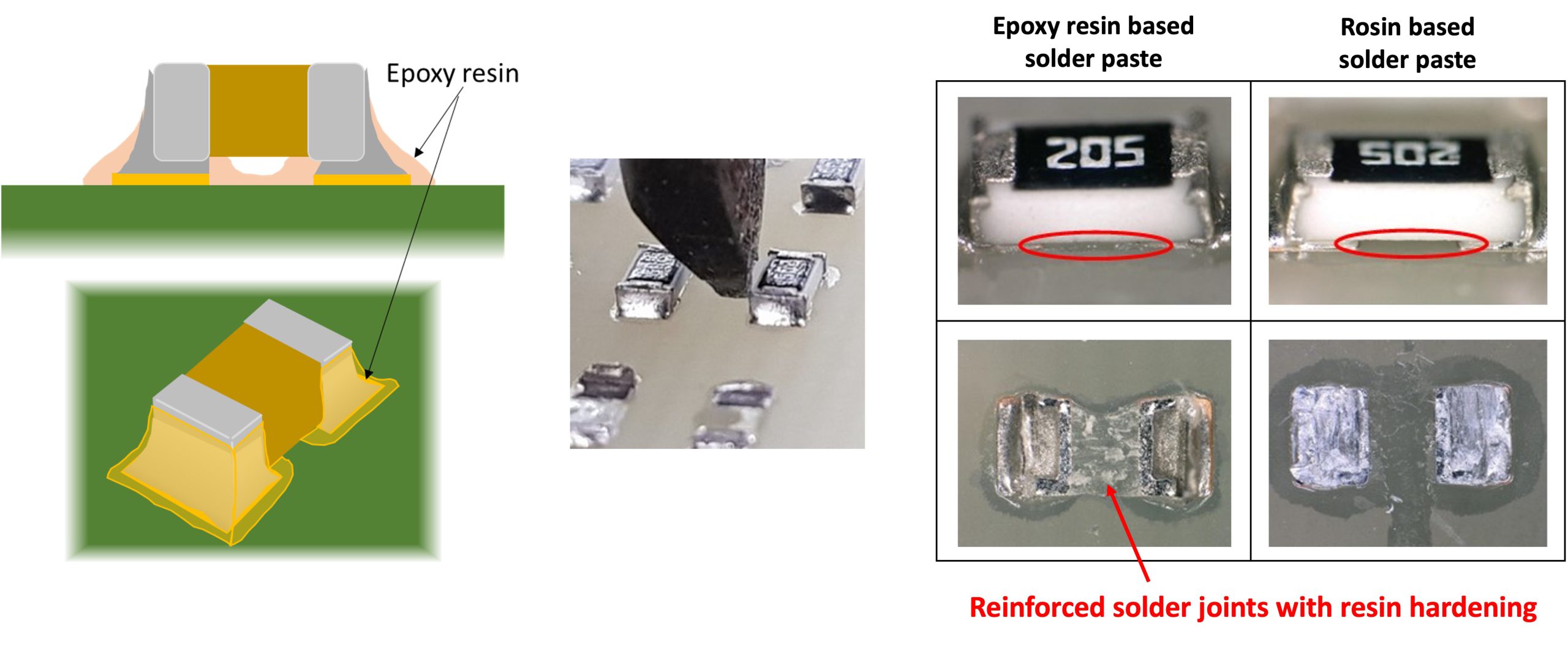

Epoxy Resin

Low Temperature Solder

SB58-EPP/EPC101-T4

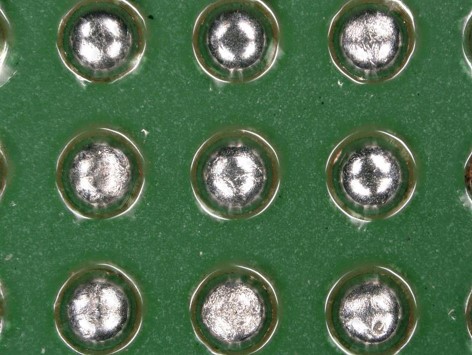

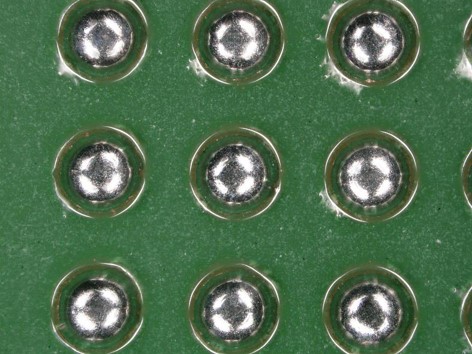

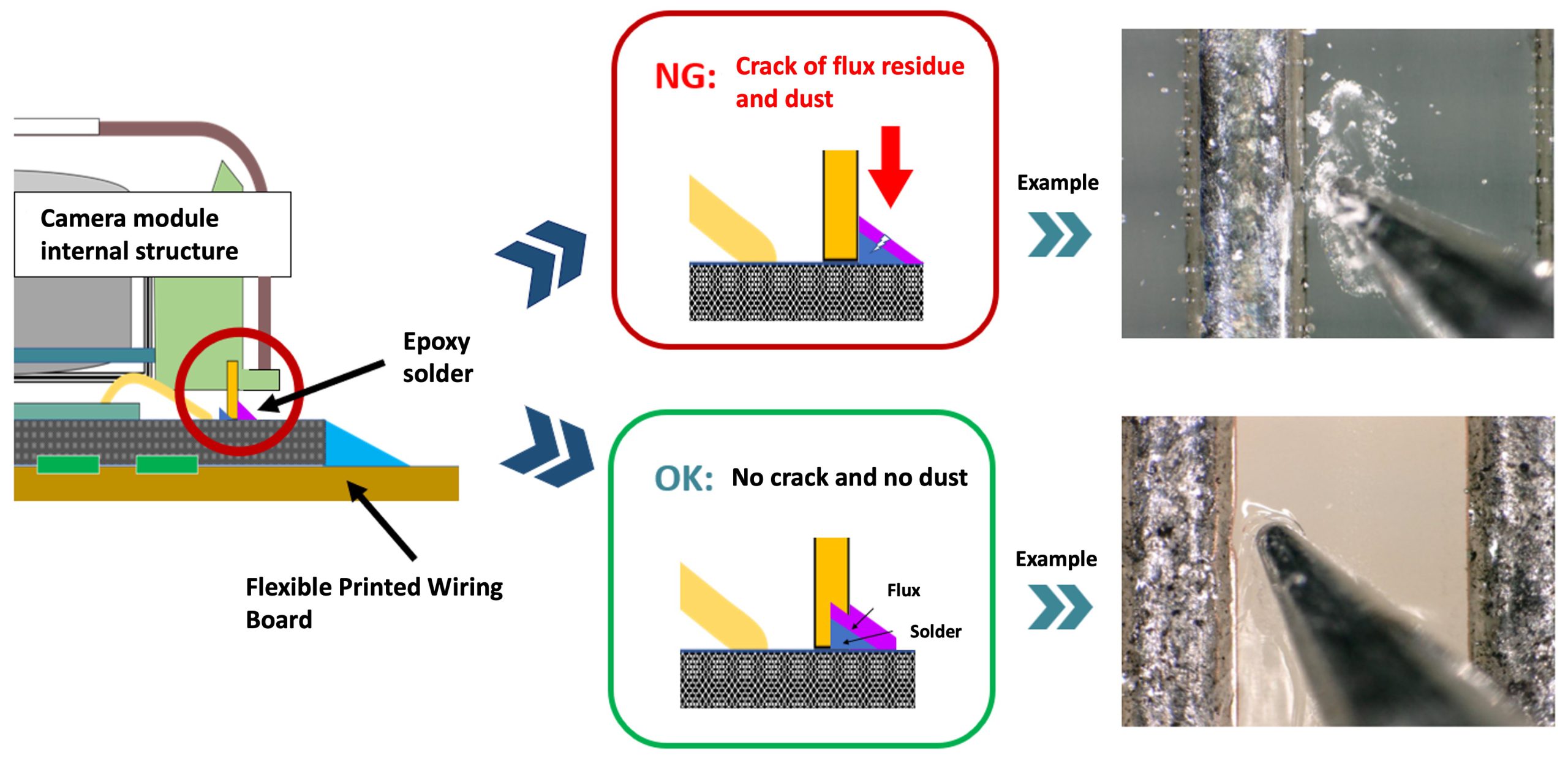

Dust from Flux Residue after Soldering

The epoxy resin that sticks the flux residue prevents optical components such as lenses from contamination.

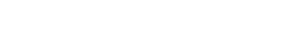

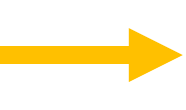

Shear Strength after Reflow Soldering(for 0603 Sized Chip Component)

Compared to conventional rosin based flux paste, there is high shear strength and less deterioration after thermal shock test.

|

Initial Shear Strength (kgf)

|

-40°C~125°C 100 Cycles

|

Shear Strength after 100 heat cycle at -40°C~125°C (kgf)

|

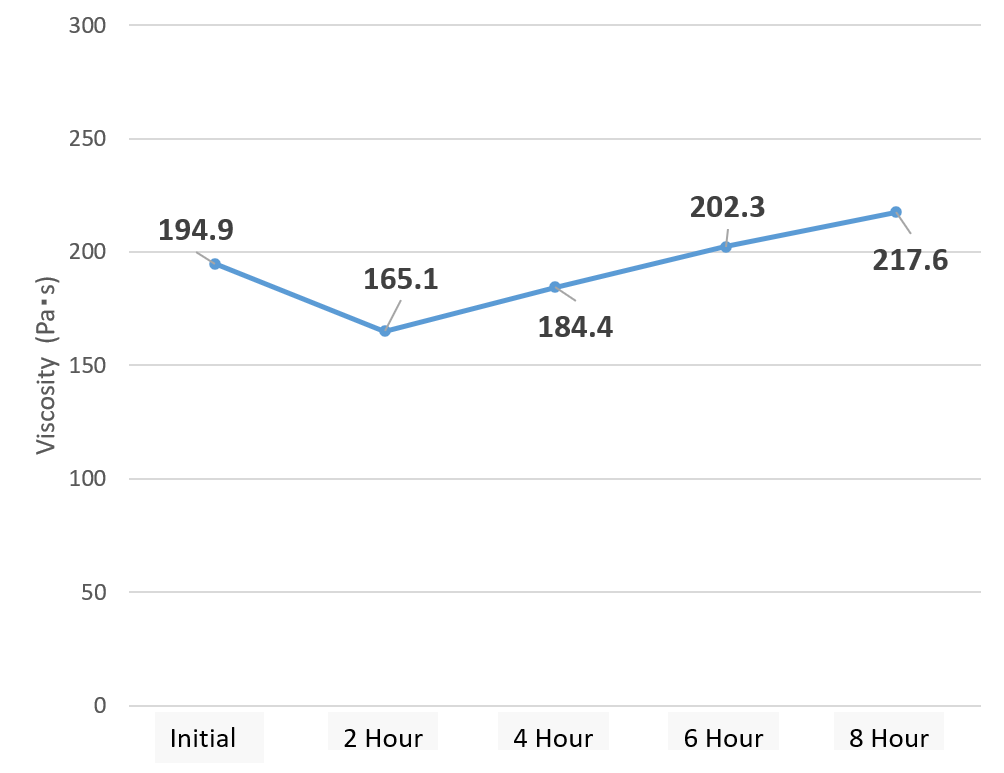

Print Stability during Use

Maintains viscosity and solderability without significant changes for up to 8 hours of continuous printing.

|

Viscosity Change with Continuous Printing

|

Initial

|

|

After 8 Hours

|