Solder Paste

NEW

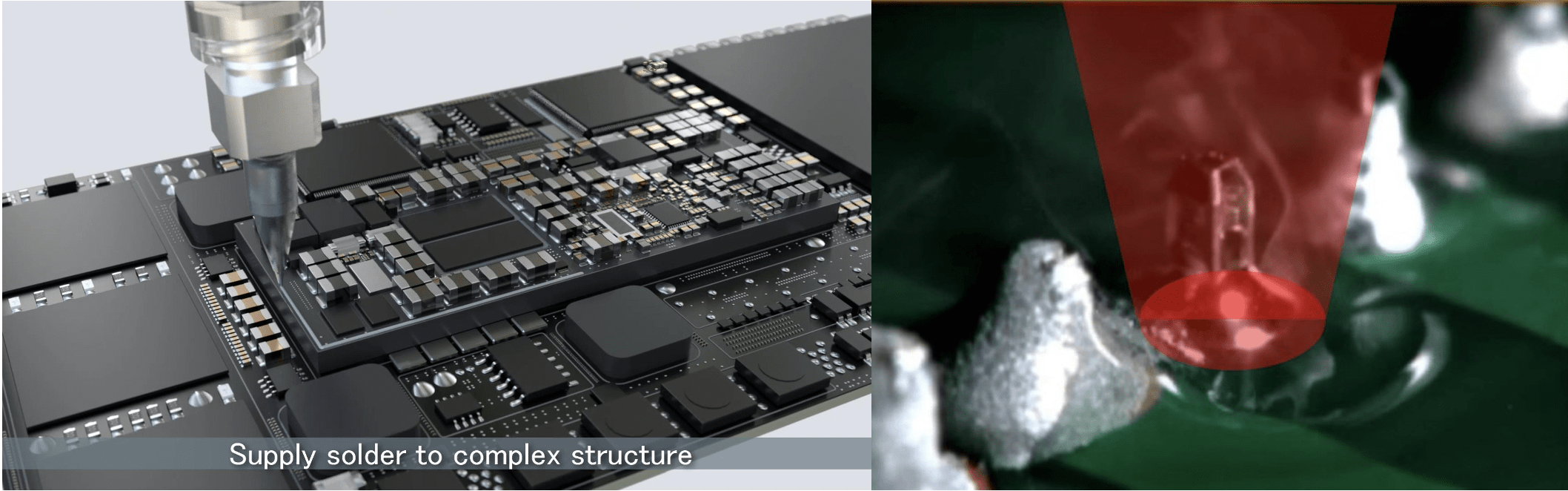

For Air Pressure Dispensing and Laser Soldering

NP303-DPS101-T4/T5

Solder Paste with Excellent Continuous Stable Dispensing

and to be Applicable for Laser Soldering.

Stable Dispensability and Excellent Solderability with Rapid Laser Heating even with Halogen-Free

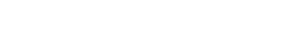

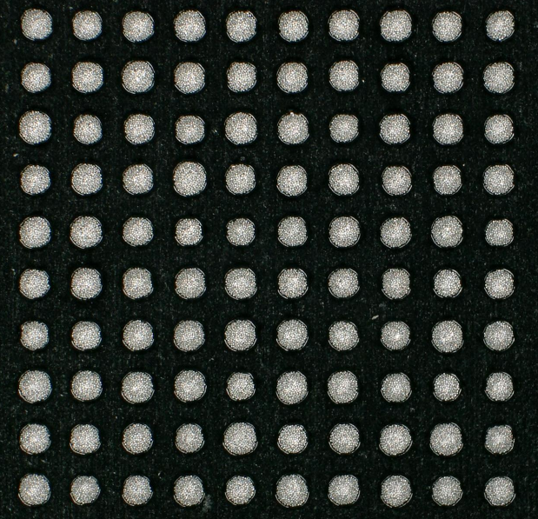

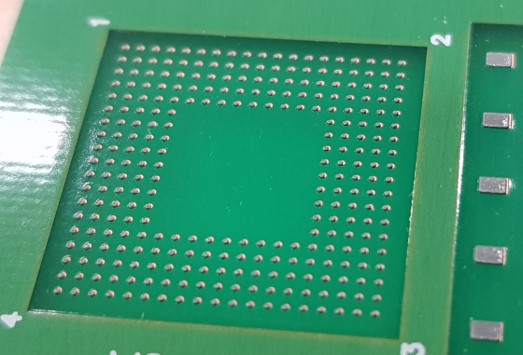

Stable Dispensing Appearance

Type5 Solder Paste

Keep Stable Dispensing after 300,000 Shots

Dispinsing Diameter: 300μm

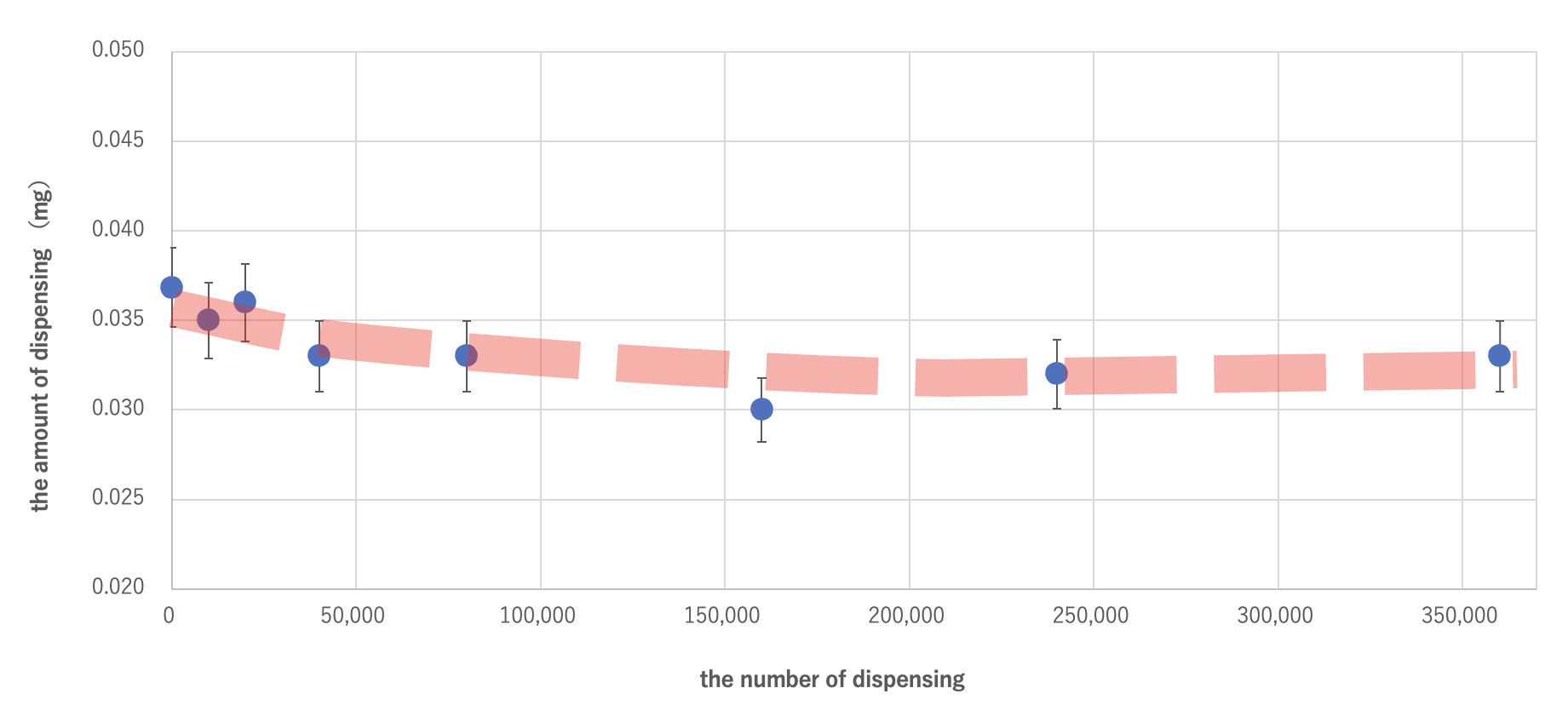

Continuous Stable Volume of Dispensing

The Number of Dispensing Change with the Amount of Dispensing

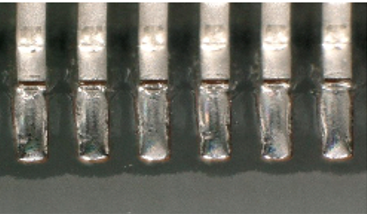

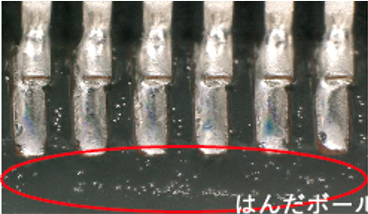

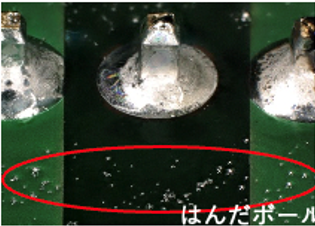

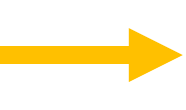

Comparison of Solder Melting during Laser Heating

Compared to conventional products, wettability is improved and spattering is reduced by about 30%.

|

QFP

|

Connectors

|

|

|

NP303-DPS101-T4/ T5

|

|

|

| Conventional Products |  |

|

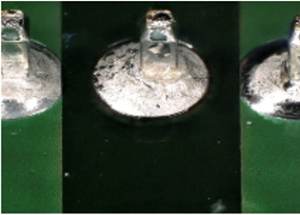

Reflow Test by Area-Laser

|

Printed Solder Paste of NP303-DPS101-T4

|

Local Reflow by Area-Laser

|

|

|

|

|

Equipment: Selective Reflow Equipment of Laserssel Co. ( Cooperated with Techno Alpha Co.)

|

Characteristics NP303-DPS101-T4/T5

|

||||

|

Alloy Composition

|

Sn-3.0Ag-0.5Cu

|

|

||

|

Melting Point

|

217℃~219℃

|

♦ For Air Pressure Dispensing and Laser Soldering |

||

|

Powder Type

|

Type4, 5

|

|||

|

Halide Content |

<0.1wt% |

|||