Solder Paste

Low Ag

PW233-ST355-GQ-4

0.3Ag Composition Solder Paste

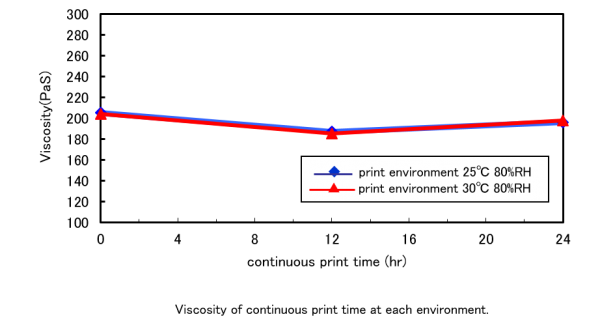

Excellent Stability of Viscosity under Hot and Humid Environment

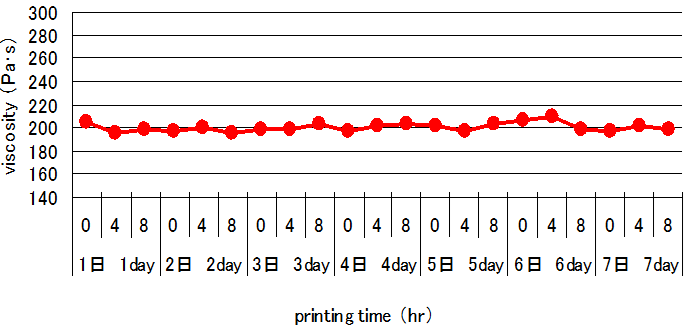

Excellent Continuous Printing Performance while Adding Paste

Test Result of Continuous Printing under High Temperature and Humidity

Able to use even under hot and humid environment with minimal change of viscosity.

Test Result of Continuous Printing while Adding Paste

When printing while adding paste, there is almost no deterioration in properties even after 7 days of use.

Printing Condition

Squeegee: Metal Type, Angle 60°, Width 280mm

Squeegee Stroke: 25cm

Printing Speed: 30mm/ sec

Printing Pressure: 22 x 10-2N

Interval: 30sec

Environment: Temperature 26°C~28°C Humidity 30%~50%

Place a 500g of solder paste on the stencil, 250g solder paste from the machine will replace with new solder paste after 4 hours. Collect the remaining solder paste after 8 hour printing and keep it in the refrigerator for 16 hours. This process will repeat for 7 days.

Viscosity of Adding Solder Paste while Printing for 7 days

|

1st day

|

7th day

|

||

|

Printability (0.4mm pitch QFP)

|

|

|

|

|

Melting (0.4mm pitch QFP) |

|

|

The Solder Paste Condition after Printing for 7 Days (Excellent) |

|

Characteristics PW233-ST355-GQ-4

|

||||

|

Alloy Composition

|

Sn-0.3Ag-3.0Bi-0.5Cu

|

|

||

|

Melting Point

|

207℃~224℃

|

♦ Low Ag |

||

|

Powder Type

|

Type4

|

♦ Ensuring Strength while Reducing Cost | ||

|

Halide Content |

0.02wt%±0.01 |

|||