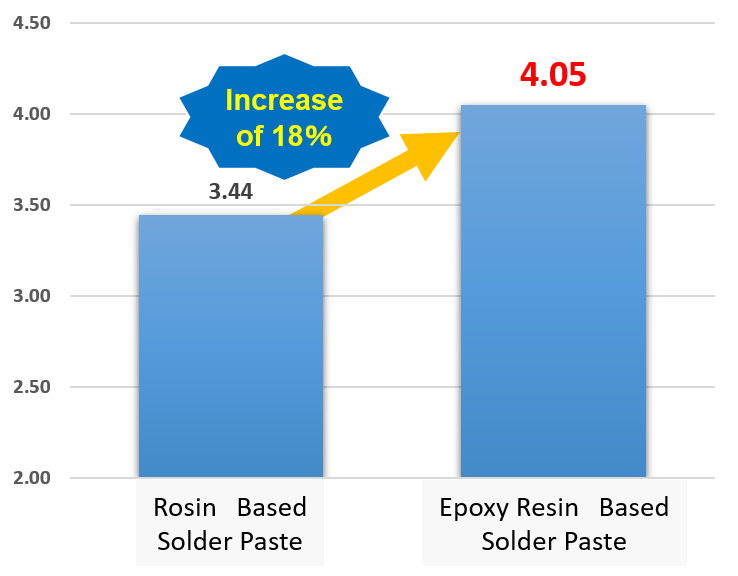

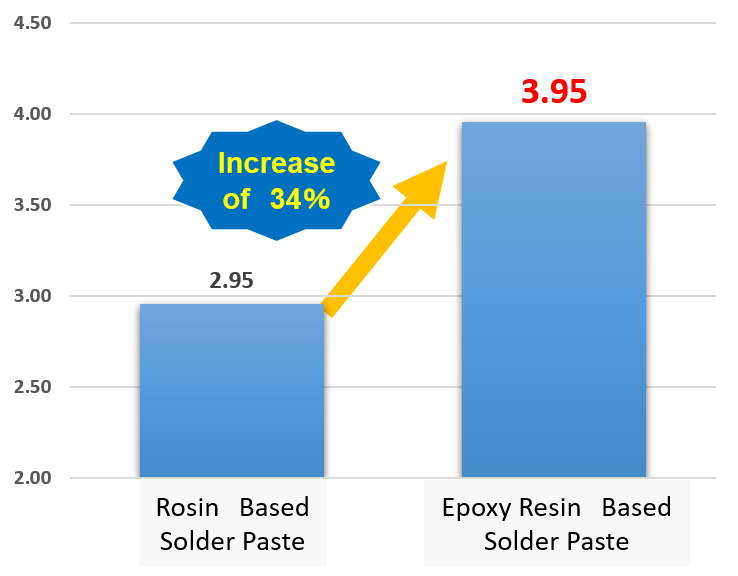

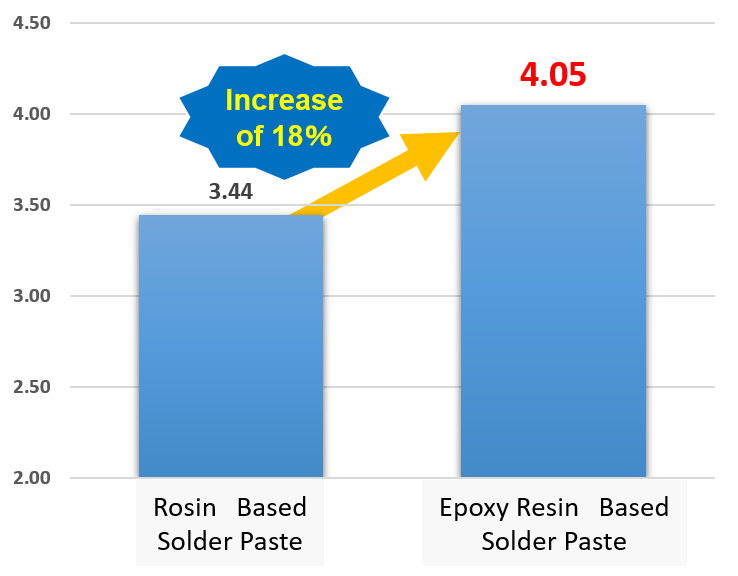

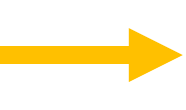

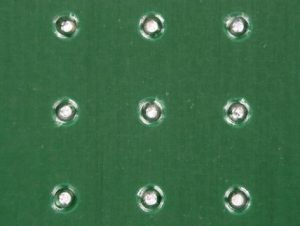

Shear Strength after Reflow Soldering(for 0603 Sized Chip Component)

Compared to conventional rosin based flux paste, there is high shear strength and less deterioration after thermal shock test.

|

Initial Shear Strength (kgf)

|

-40°C~125°C

100 Cycles

|

Shear Strength after 100 Heat Cycle

at -40°C~125°C (kgf)

|

|

Shear Tester:

Tension Testing MAchine

SEISHIN SS-39WD

|

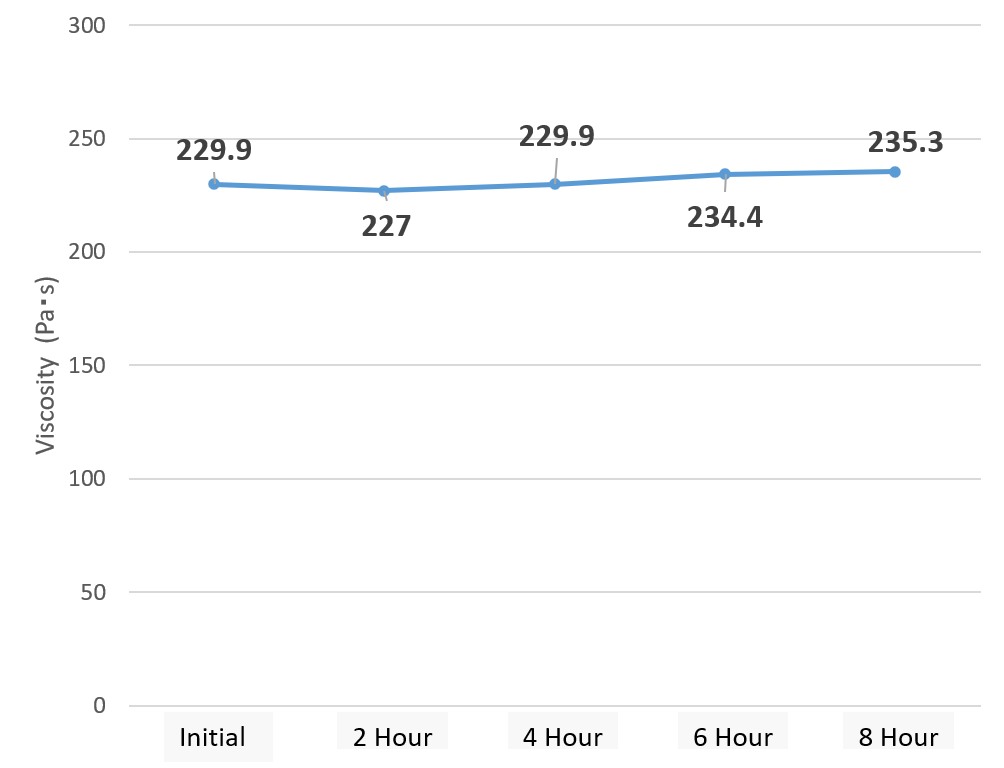

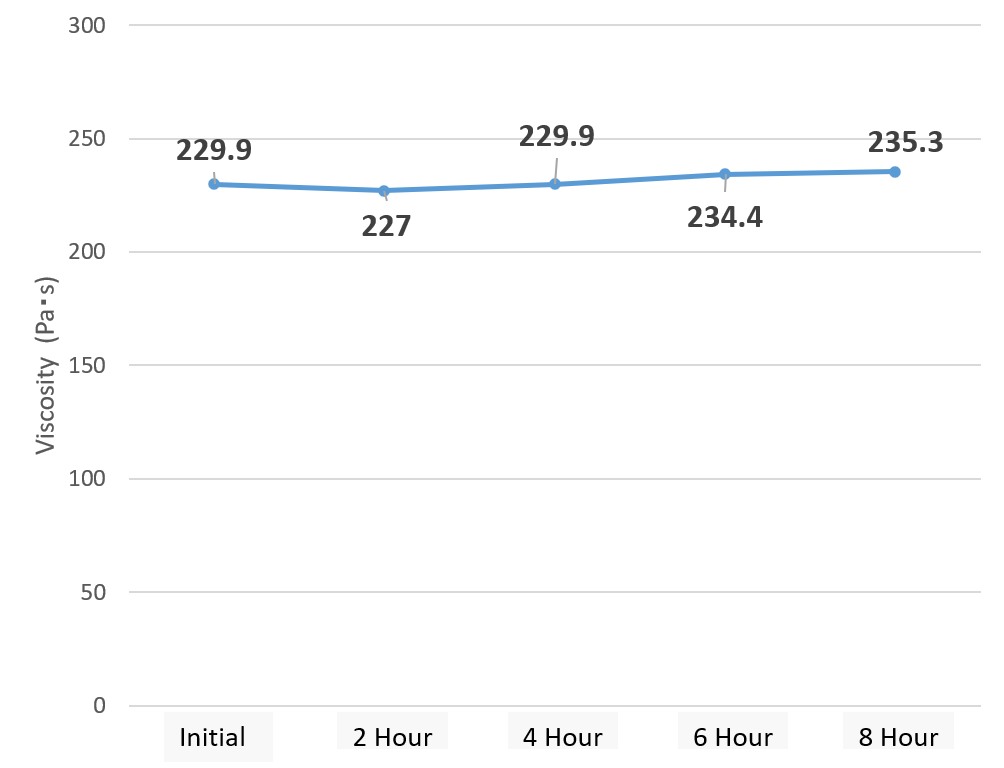

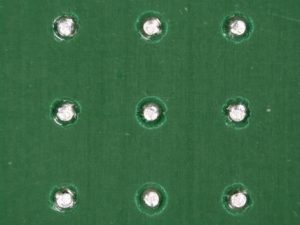

Print Stability during Use

Maintains viscosity and solderability without significant changes for up to 8 hours of continuous printing.

|

Viscosity Change with Continuous Printing

|

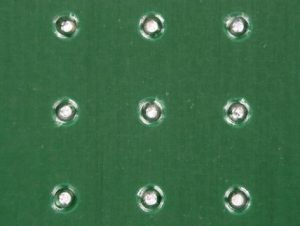

Initial

|

|

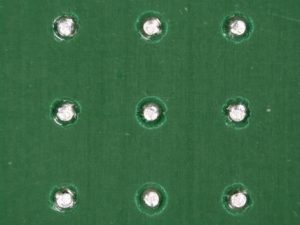

After 8 Hours

|

|

Characteristics NP303-EPP101-T4 NP303-EPC101-T4

|

|

|

|

Supply of

Solder Paste

|

Printing

|

Dispensing

|

|

|

|

Alloy Composition

|

Sn-3.0Ag-0.5Cu

|

|

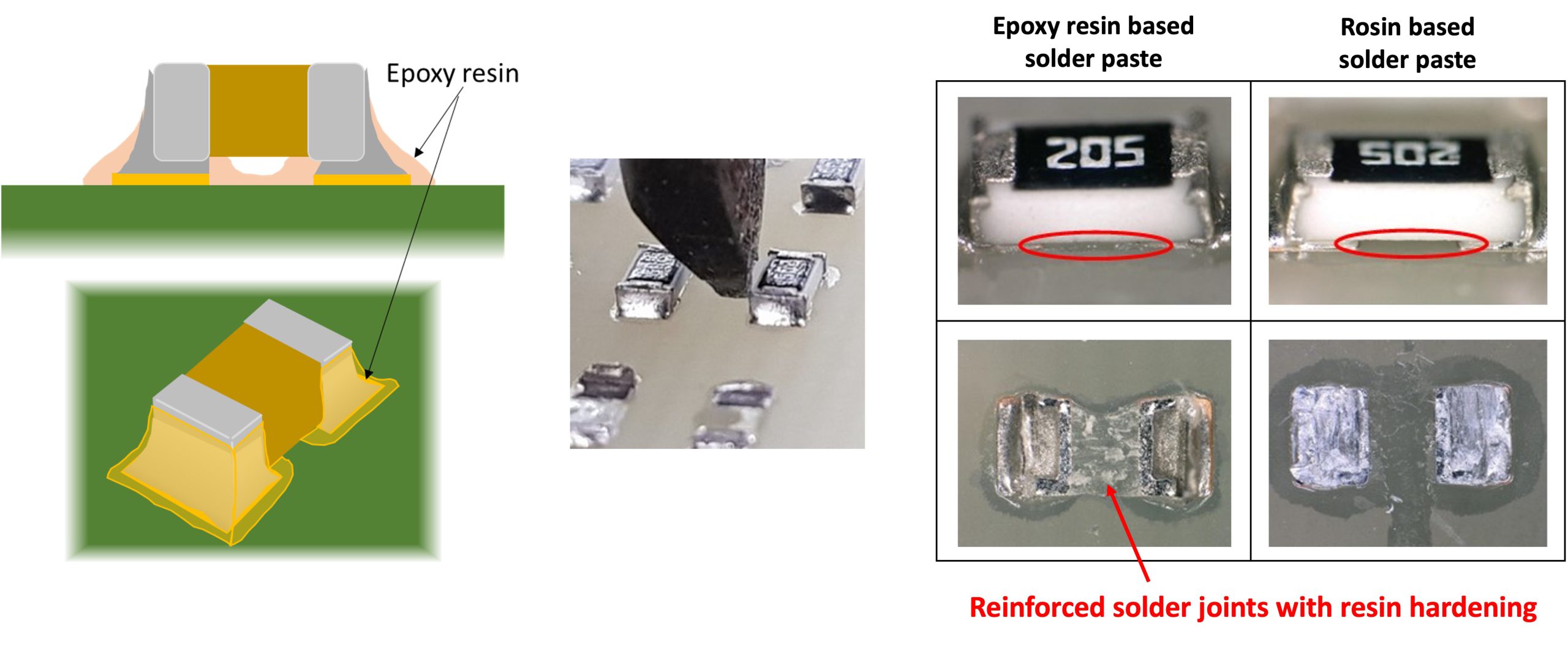

♦ Epoxy Resin

|

|

Powder Type

|

Type4、5、6

|

|

♦ Strength of Solder Joint

|

|

Halide Content

|

<0.05wt%

|

|

|

|

Reflow Oven

|

Possible under air reflow oven

(N2 reflow oven necessary for type5 and type 6)

|

|

|

|

Storage Condition

|

<-15℃

|

|

Customizing possible according to the product and the process. |