Solder Paste

NEW

Fine Soldering for Mini/Micro LED

NP303-GSD003-T6

Stable Printability in order to Mount a lot of Mini LEDs on Display Substrates

|

NG |

|

OK |

||

|

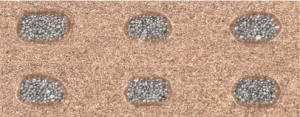

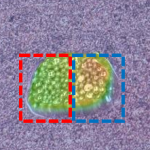

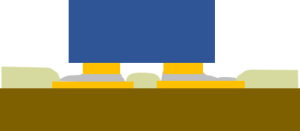

LED Chips not Standing Flat after Mounting

|

WHY

♦ The supply of solder paste is uneven. When solder paste is too much or too less, it would cause the tombstone defect.

♦ Solder paste is wetting unevenly. |

|

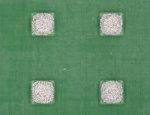

WHY

♦ The supply of solder paste is even.

♦ Solder paste is wetting evenly. |

|

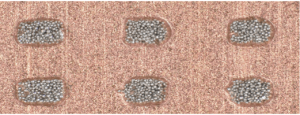

By adjusting the viscosity and thixotropy, printability is improved and the tombstone defect is prevented.

|

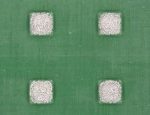

Conventional Product |

|

NP303-GSD003-T6 |

|

|

|

|

|

Solder Paste after Printing with Unequal Height |

|

Solder Paste after Printing with Equal Height |

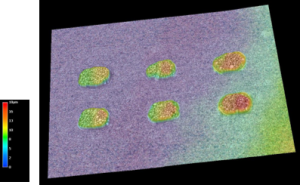

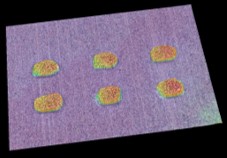

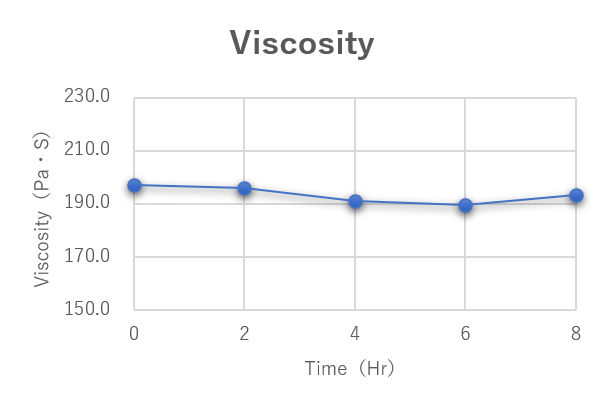

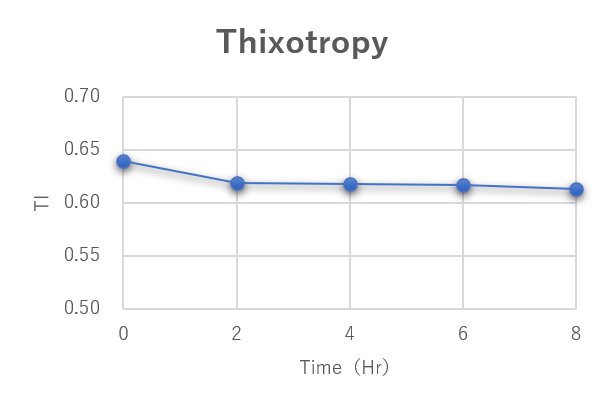

Stability of Solder Paste during 8 Continuous Printing

⊳Minimize viscosity’s and thixothropy’s reduction during the continuous printing.

⊳With ∅100µm square aperture, printability and solderability are maintained.

|

|

|

0 Hr |

4 Hr |

8 Hr |

|

| Excellent Printability |

|

|

|

| Excellent Solderability |

|

|

|

|

Characteristics NP303-GSD003-T6

|

||||

|

Alloy Composition

|

Sn-3.0Ag-0.5Cu

|

|

||

|

Melting Point

|

217℃~219℃

|

♦ Fine Soldering for Mini/ Micro LED |

||

|

Powder Type

|

Type6, 7, 8

|

|||

|

Halide Content |

<0.05wt% |

|||